It’s been over 10 years since Honest Wheel Bikes in Tucson, AZ first shared with us their impartial bar & stem testing, however they’re again at it, measuring actual stiffness in a brand new crop of 15 trendy street & gravel bike stems. What do you favor: absolute lightest weight, most stiffness, the very best stiffness:weight ratio, or perhaps some pleased medium which may not break the financial institution. Honest Wheel does the testing so we are able to all make extra knowledgeable shopping for choices.

Honest Wheel Bikes checks actual street & gravel bike stem stiffness

So why did Honest Wheel mud off their take a look at rig? We spoke to long-time head of the store Jason Woznick, and he stated merely that, “it has been a couple of decade since we did testing…. [and] we needed to re-test, bars, stems and cranks and see how issues have modified.”

Sounds good to us.

I’ve personally recognized Honest Wheel since round 2001 or so. That’s once I was first launched to the store and their weight-weenie methods by a buddy who’d labored in there earlier than shifting to the East Coast. After which, quickly after I headed to satisfy them in Tucson in individual when touring out to race the 24 Hours within the Previous Pueblo. Honest Wheel bikes has catered to each native in search of trusted service, and bike nerds from far & broad searching probably the most unique elements and among the world’s lightest bike builds.

Though we didn’t get to it then, Honest Wheel lately celebrated their Fiftieth-anniversary final yr by updating their street crankarm and handlebar stiffness checks with some extra of the most recent & biggest trendy fashions. You’ll be able to take a look at that Could 2023 street crank take a look at right here or their up to date November 2023 street bar take a look at right here.

However now let’s get again to stems.

Why will we belief Honest Wheel Bike’s impartial element testing?

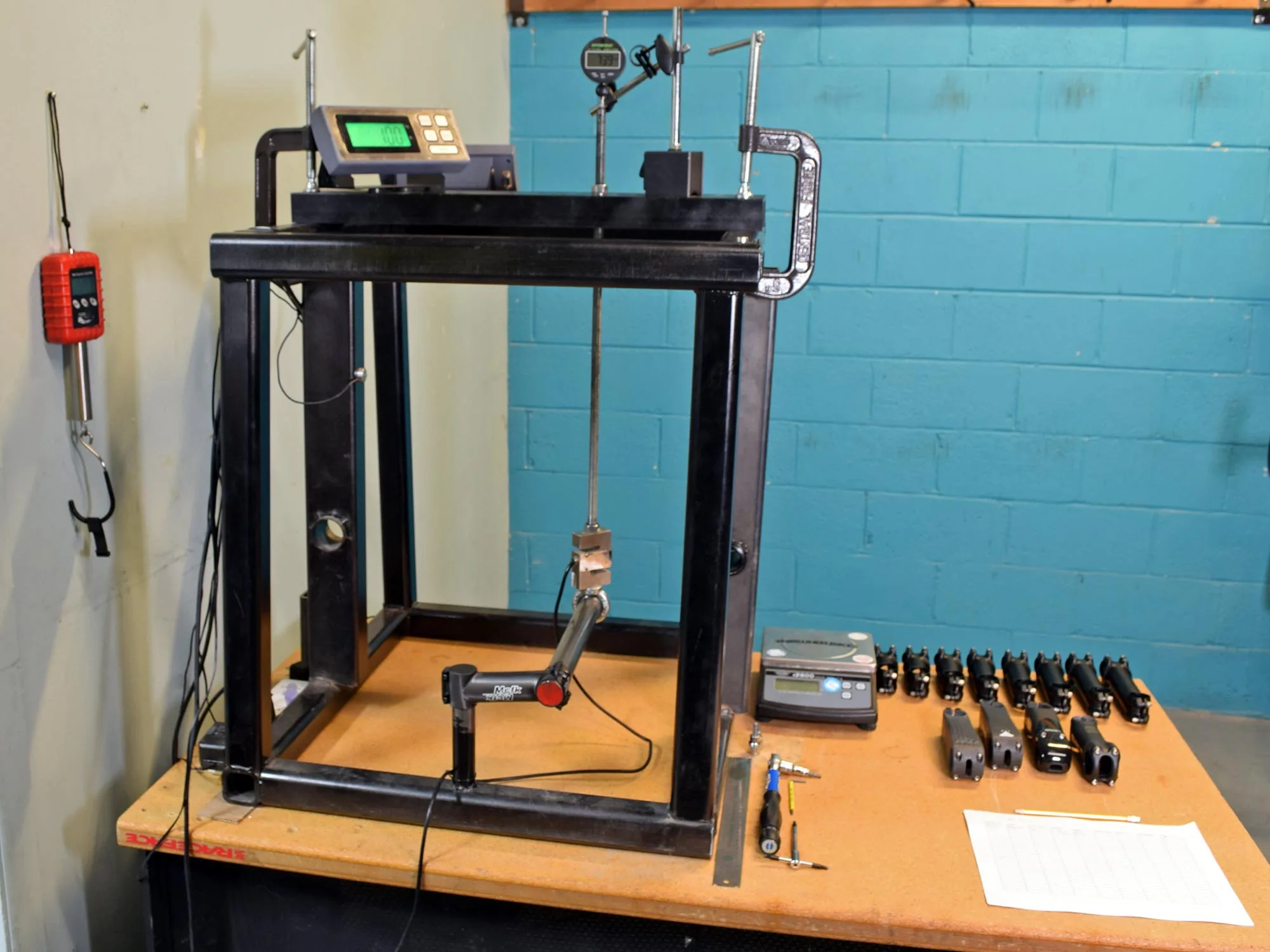

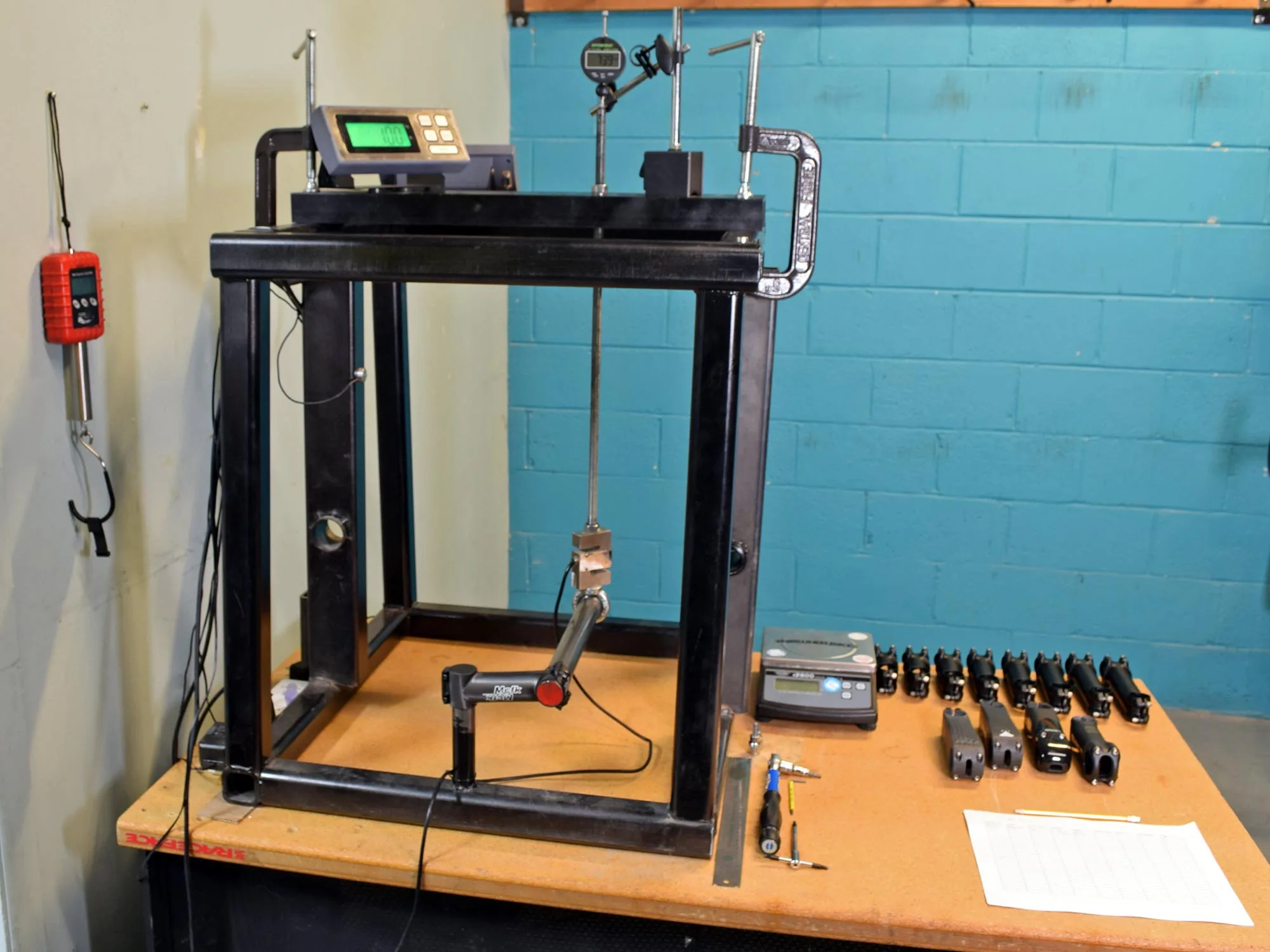

The great thing about Honest Wheel Bikes testing elements is three-fold. First, they’ve been round for greater than half a century, and so they stored the identical take a look at rig at the back of the store simply ready. Secondly, they’re tremendous analytical however sensible, so that they preserve their checks easy and use the very same take a look at protocol as we speak as after they began testing elements.

And lastly, they’re sort of a bunch of nerds. OK, positively fellow bike nerds… our favourite sort.

Try their unique 2014 stem checks, right here.

Stem deflection testing methodology

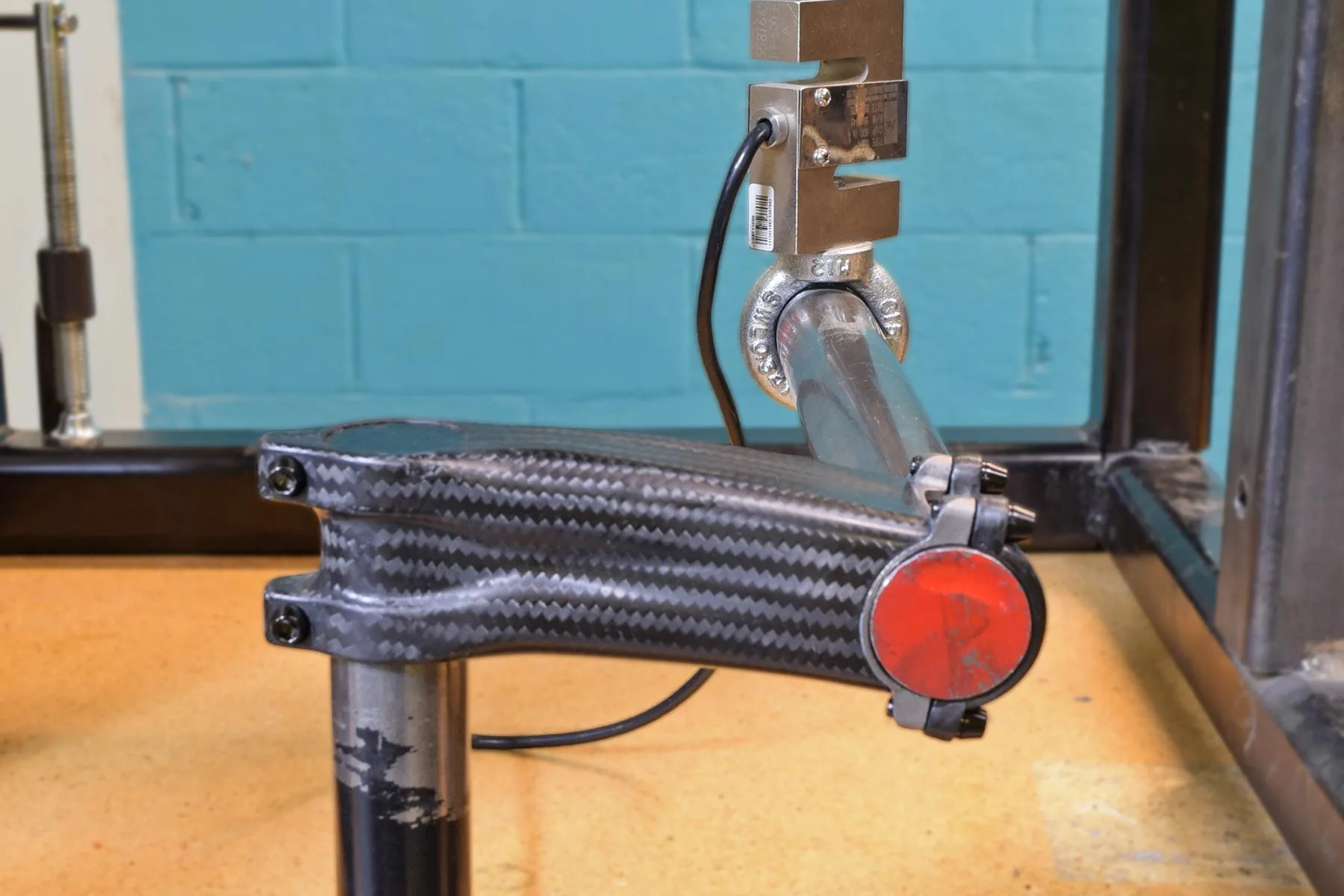

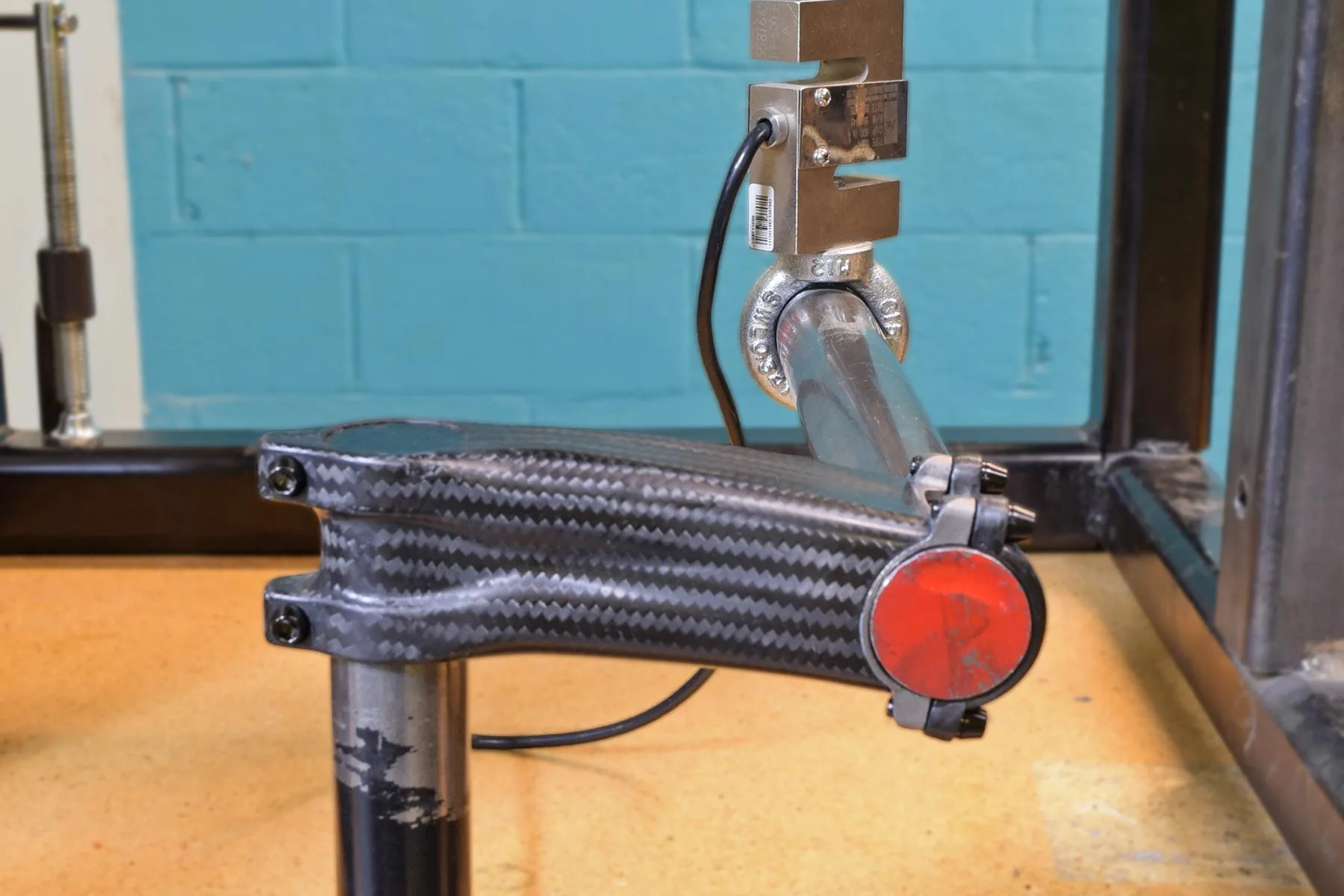

Their stem stiffness testing is simply measuring stem deflection – how far a stem bends underneath a repeatable load. Once more, Honest Wheel introduced again their “favourite engineer” Jason Krantz to run the checks. He’s now a mechanical engineer at a worldwide firm growing testing & measurement tools. However he additionally labored within the biking trade over his profession, for instance designing bikes at Titus and sharing our journalistic focus at Bicycle Retailer and Trade Information again within the 90s.

The stem deflection testing protocol he developed fixes the stem in a inflexible body, then applies a uniform 100lb (~45kg) load 10″ (~25cm) away from the centerline of the stem. The take a look at simulates an affordable approximation of the power when a rider is sprinting, pulling towards the bar – up on one aspect, down on the opposite – as they attempt to pedal as onerous as doable. However the precise power/load/weight doesn’t actually matter, as deflection is linear, and they’re evaluating all stems with the identical forces.

Honest Wheel has tried to reduce variables as a lot as doable. Their methodology says all stems ought to be 110mm lengthy and -6° of rise, with a 1.125″ steerer clamp and 31.8mm bar clamp. However some stems examined weren’t obtainable in that precise measurement, so there’s +1° variability in angle and -5mm variability for simply two stems (105mm Professional Vibe Dash Carbon & Syntace F119). However they clarify why which will or might not matter.

What’s stiffness?

One thing of a disclaimer… neither Honest Wheel nor us at Bikerumor are essentially saying that better stiffness truly means a greater stem.

Possibly some lighter and even all-road & gravel riders would possibly like a little bit of compliance of their stem?

And the Honest Wheel take a look at doesn’t even contact on the potential vibration damping that some supplies can present, independently of stiffness.

However in case you are in search of cockpit rigidity for some discount of vitality loss or improved dealing with efficiency advantages, stem stiffness is actually a superb place to start out in comparisons. And so, we’re fairly psyched that Honest Wheel is there out crunching these numbers for everybody to see.

Scroll right down to the underside of this text if you wish to learn Honest Wheel’s personal detailed description.

2024 Honest Wheel stem stiffness checks’ outcomes

High 5 Stiffest

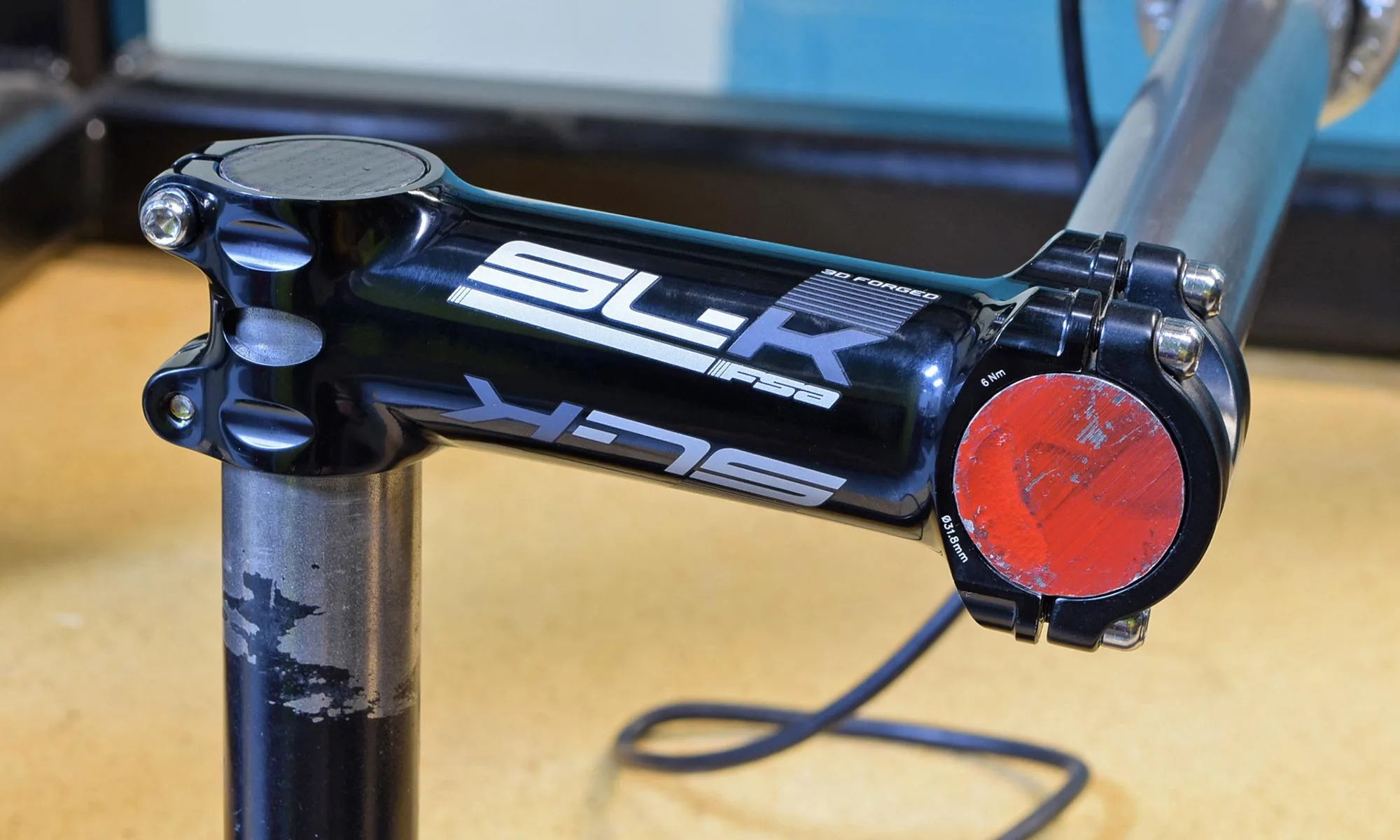

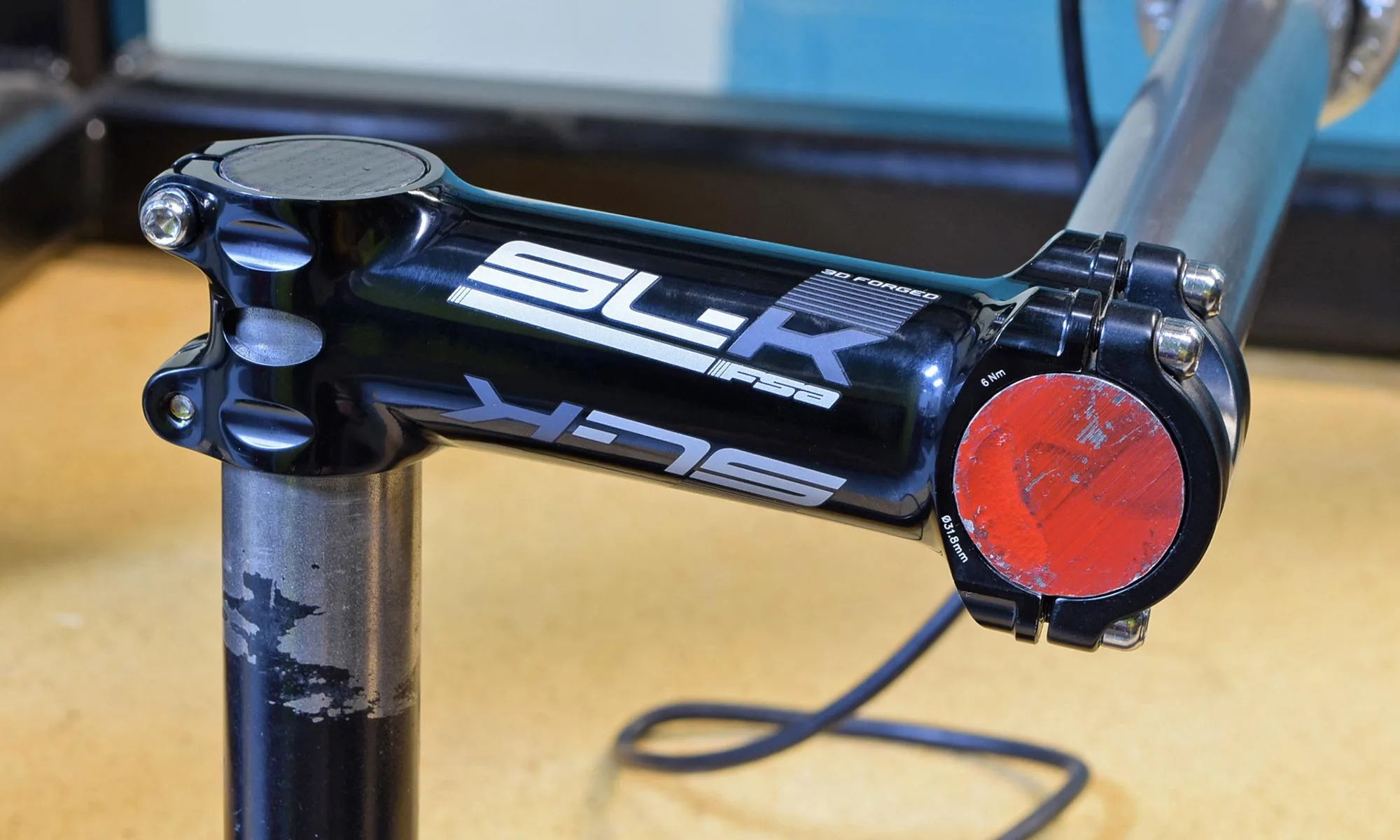

- FSA SL-Okay at simply 3.7mm deflection, made from 2014 aluminum with metal bolts

- FWB machined Ti prototype at simply 3.7mm deflection, made from titanium with ti bolts

- Ritchey Superlogic C260 at simply 3.7mm deflection, made from 2024 aluminum with metal bolts

- ENVE Carbon at simply 4.2mm deflection, made from carbon with ti bolts

- Uno Stealth at simply 4.5mm deflection, made from 2024 aluminum with stainless-steel bolts

High 5 Lightest

- Extralite Hyperstem at 82.5g from 7075 aluminum with titanium bolts

- THM Tibia at 91g from carbon with titanium bolts

- MCFK Carbon at 92.3g from carbon with titanium bolts

- Schmolke TLO (ICR) at 94.5g from carbon with titanium bolts

- Uno Stealth at 104.7g from aluminum with stainless-steel bolts

High 5 Stiffness:Weight Ratio

- Extralite Hyperstem with 5.6mm deflection at 82.5g for a 2.16 S/W ratio

- Uno Stealth with 4.5mm deflection at 104.7g for a 2.12 S/W ratio

- Ritchey WCS C260 with 4.7mm deflection at 108.1g for a 1.97 S/W ratio

- Ritchey Superlogic C260 with 4.1mm deflection at 128g for a 1.91S/W ratio

- FSA SL-Okay with 3.7mm deflection at 144g for a 1.88 S/W ratio

Full 2024 Check Information

| mfg | mannequin | Deflect avg (mm) |

Weight (g) |

S/W | stem materials |

bolt materials |

angle (deg) |

|---|---|---|---|---|---|---|---|

| Bjorn | prototype | 5 | 110.9 | 1.8 | Carbon/Ti | Titanium | 6° |

| ENVE | Carbon | 4.2 | 131 | 1.82 | Carbon | Titanium | 6° |

| ENVE | Aero Highway In-Route | 4.8 | 177 | 1.18 | Carbon | Titanium | 7° |

| ENVE | Aero Highway | 5 | 170 | 1.18 | Carbon | Titanium | 7° |

| Extralite | Hyperstem | 5.6 | 82.5 | 2.16 | 7075 alloy | Titanium | 6° |

| FSA | SL-Okay | 3.7 | 144 | 1.88 | 2014 alloy | Metal | 6° |

| FWB Ti | machined prototype | 3.7 | 149.2 | 1.81 | Titanium | Titanium | 7° |

| FWB Ti | welded prototype | 4.9 | 139.2 | 1.47 | Titanium | Titanium | 7° |

| MCFK | Carbon | 6.8 | 92.3 | 1.59 | Carbon | Titanium | 6° |

| Ritchey | Superlogic C260 | 4.1 | 128 | 1.91 | Carbon | Metal | 6° |

| Ritchey | WCS C260 | 4.7 | 108.1 | 1.97 | 7050 alloy | Metal | 6° |

| Schmolke | TLO (ICR) | 5.8 | 94.5 | 1.82 | Carbon | Titanium | 6° |

| THM | Tibia | 6.1 | 91 | 1.8 | Carbon | Titanium | 6° |

| Uno Stealth | 110 | 4.5 | 104.7 | 2.12 | 7050 alloy | Stainless | 7° |

| Uno Stealth | 110 | 4.5 | 117 | 1.9 | 7050 alloy | Stainless | 7° |

Mixed 2014 & 2024 Check Information

| mfg | mannequin | yr examined | Deflect avg (mm) |

Weight (g) |

S/W | stem materials |

bolt materials |

angle (deg) |

|---|---|---|---|---|---|---|---|---|

| 3T | Arx Workforce | 2014 | 3.8 | 129.4 | 2.03 | 7075 alloy | Titanium | 6° |

| Bjorn | prototype | 2024 | 5 | 110.9 | 1.8 | Carbon/Ti | Titanium | 6° |

| Bontrager | XXX | 2014 | 4.59 | 129.8 | 1.68 | Carbon | Metal | 7° |

| Management Tech | Ti-Mania | 2014 | 4.01 | 132.1 | 1.89 | Titanium | Titanium | 5° |

| ENVE | Carbon | 2024 | 4.2 | 131 | 1.82 | Carbon | Titanium | 6° |

| ENVE | Aero Highway In-Route | 2024 | 4.8 | 177 | 1.18 | Carbon | Titanium | 7° |

| ENVE | Aero Highway | 2024 | 5 | 170 | 1.18 | Carbon | Titanium | 7° |

| ENVE | Carbon | 2014 | 4 | 120.1 | 2.07 | Carbon | Titanium | 6° |

| Extralite | Hyperstem | 2024 | 5.6 | 82.5 | 2.16 | 7075 alloy | Titanium | 6° |

| Extralite | Hyperstem | 2014 | 5.76 | 81.4 | 2.29 | 7075 alloy | Titanium | 6° |

| Extralite | OC Highway | 2014 | 5.26 | 87.7 | 2.25 | 7075 alloy | Titanium | 8° |

| Far and Close to | S1 | 2014 | 3.92 | 144 | 1.77 | 6061 alloy | Metal | 6° |

| FSA | SL-Okay | 2024 | 3.7 | 144 | 1.88 | 2014 alloy | Metal | 6° |

| FSA | SL-Okay | 2014 | 3.78 | 167.2 | 1.58 | 2014 alloy | Metal | 6° |

| FWB Ti | machined prototype | 2024 | 3.7 | 149.2 | 1.81 | Titanium | Titanium | 7° |

| FWB Ti | welded prototype | 2024 | 4.9 | 139.2 | 1.47 | Titanium | Titanium | 7° |

| KCNC | Arrow | 2014 | 4.28 | 138.6 | 1.68 | 7050 alloy | Titanium | 7° |

| KCNC | Flyride | 2014 | 4.55 | 127.3 | 1.72 | 6061 alloy | Metal | 5° |

| MCFK | Carbon | 2024 | 6.8 | 92.3 | 1.59 | Carbon | Titanium | 6° |

| Mcfk | Carbon | 2014 | 6.74 | 88.6 | 2.39 | Carbon | Titanium | 6° |

| New Final | Evo | 2014 | 5.3 | 110.8 | 1.7 | 7050 alloy | Titanium | 6° |

| Professional | Vibe 7S | 2014 | 4.06 | 137.3 | 1.79 | 7075 alloy | Metal | 10° |

| Professional | Vibe Carbon | 2014 | 5.24 | 138.4 | 1.38 | Carbon/7075 | Titanium | 10° |

| Professional | Vibe Dash Carbon (105mm) | 2014 | 2.69 | 199.4 | 1.87 | Carbon | Metal | 10° |

| Professional | Vibe Monitor Carbon | 2014 | 2.73 | 186.9 | 1.96 | Carbon | Metal | 10° |

| Professional | XCR | 2014 | 5.38 | 117.6 | 1.58 | 7075 alloy | Metal | 5° |

| Race Face | Turbine | 2014 | 4.38 | 144 | 1.59 | 7075 alloy | Metal | 6° |

| Ritchey | WCS C260 | 2024 | 4.7 | 108.1 | 1.97 | 7050 alloy | Metal | 6° |

| Ritchey | Superlogic C260 | 2024 | 4.1 | 128 | 1.91 | Carbon | Metal | 6° |

| Ritchey | 260 | 2014 | 4.81 | 113.5 | 1.83 | 7075 alloy | Metal | 6° |

| Ritchey | 260 Carbon | 2014 | 4.67 | 128 | 1.67 | Carbon | Metal | 6° |

| Ritchey | 4-Axis Carbon | 2014 | 5.73 | 120.2 | 1.45 | Carbon/7075 | Titanium | 6° |

| Schmolke | TLO (ICR) | 2024 | 5.8 | 94.5 | 1.82 | Carbon | Titanium | 6° |

| Syntace | F119 (105mm) | 2014 | 4.55 | 132.2 | 1.66 | 7075 alloy | Metal | 6° |

| THM | Tibia | 2024 | 6.1 | 91 | 1.8 | Carbon | Titanium | 6° |

| Thomson | X2 | 2014 | 4.2 | 146.8 | 1.62 | 7000 alloy | Metal | 10° |

| Thomson | X4 | 2014 | 3.41 | 168.2 | 1.74 | 7000 alloy | Metal | 10° |

| Tune | 4 | 2014 | 4.47 | 109.4 | 2.04 | 7075 alloy | Titanium | 8° |

| Uno Stealth | 110 | 2024 | 4.5 | 104.7 | 2.12 | 7050 alloy | Stainless | 7° |

| Uno Stealth | 110 | 2024 | 4.5 | 117 | 1.9 | 7050 alloy | Stainless | 7° |

Bonus stem stiffness content material

Quoting Woznick once more, “If you happen to’ve made it this far, you’re in all probability fairly within the matter on the whole. For some bonus content material we determined to run a take a look at of the identical stem in 8 totally different lengths. Chances are you’ll be shocked how predictable the variations within the outcomes actually are.“

| mannequin | size examined |

Deflect avg (mm) |

Weight (g) |

S/W |

|---|---|---|---|---|

| Uno Stealth | 60 | 2.91 | 90 | 3.81 |

| Uno Stealth | 70 | 3.21 | 94 | 3.31 |

| Uno Stealth | 80 | 3.59 | 98 | 2.84 |

| Uno Stealth | 90 | 3.91 | 105.2 | 2.43 |

| Uno Stealth | 100 | 4.22 | 109.5 | 2.16 |

| Uno Stealth | 110 | 4.55 | 115.8 | 1.89 |

| Uno Stealth | 120 | 4.88 | 119 | 1.72 |

| Uno Stealth | 130 | 5.1 | 124.5 | 1.57 |

My Bikerumor Takeaways from Honest Wheel’s stem checks

My first impression when wanting on the new information and evaluating it to the outdated was that on common the brand new stems are 7.1% lighter however 8.9% much less stiff, giving them a median 2.7% lower in stiffness:weight. Honest Wheel clarified a bit that we in all probability can’t so simply examine the figures general, as the person stems largely fell in comparable ranges. However they did notice that new to the 2024 testing had been some prototype titanium stems, that are stiffer, but in addition heavier, skewing the averages a bit.

It’s onerous although for me to miss that there have been already 8 stems in 2014 (out of 25) with ~4mm or much less deflection, whereas solely 2 had been so stiff within the new 2024 batch (of 15). I take that to recommend that the trade as an entire would possibly not likely be making an attempt onerous to make stems stiffer, as a lot as they’re making an attempt to enhance aerodynamics & integration.

However, wanting intently although at like stems (Ritchey & FSA, for instance the place there are basically the identical fashions in 2014 & 2024), it appears the newer iterations are both a bit lighter or a bit stiffer. That matches with the concept element engineers are attempting to incrementally enhance efficiency, even on primary elements like stems.

Honest Wheel’s Takeaways

Jason Woznick of Honest Wheel Bikes did say that he sees, “that as an trade development, stems have gotten disproportionally heavier than they’ve stiffer. That is probably resulting from extra trendy stems accommodating inner cabling. We plan on doing extra testing with extra internally routed stems to bear this out a bit extra.“

Of notice exterior of simply wanting on the numbers, Honest Wheel additionally provides that their testing exhibits for street elements “the extra aero a bar or stem is the extra compliant will probably be since flat surfaces deflect greater than a spherical one“. In order that’s additionally a bit extra context on deciphering their information.

Lastly, let’s all thank Honest Wheel for doing the work to assist us decide what elements we wish on our bikes!

Full Honest Wheel Bikes description of their stem testing course of, in their very own phrases…

Stem Deflection Testing:

We’ve as soon as once more introduced again our favourite engineer, Jason Krantz. Jason’s a mechanical engineer whose graduate work centered on the intersection of composite supplies and finite factor evaluation. Jason has labored for a number of corporations within the bicycle trade and by no means fails to amaze us with the depth of his biking associated information.

Disclaimer: Numerous typing and numbers have gone into this text and we apologize prematurely for any typos ought to they occur, however would warn that the potential for errors is current.

Some Preliminary Notes on Testing

Testing Methodology:

Every stem was mounted within the fixture and the testing carried out 3 instances after which averaged. All stems examined had been 11cm except for just a few which aren’t obtainable in these lengths. Every stem was mounted with its beneficial torque specs and preloaded with 20 kilos of power utilized 10 inches from the stem (about half manner between a street bar and mtb bar) As soon as preloaded the tools was zeroed and one other 100 kilos of power was added and a measurement recorded. The measurement was taken on the level of load, once more 10 inches from the stem centerline.

Masses Examined:

Whereas the precise load doesn’t matter as a result of the response of the construction is linear. [That is, a stem with a stiffness of 150-foot pounds per degree will deflect one degree with a torque of 150 foot-pounds and two degrees with a torque of 300 foot-pounds.] Jason chosen a load of 100 kilos as a result of it’s a pleasant spherical quantity, and fairly lifelike to what some riders might expertise.

For a sprinting rider, let’s say he’s pushing on the left pedal with 300lbf (in different phrases, he can squat 600lbs). The pedal is about half as removed from the body centerline because the handlebar is, so it could take a response power of 150lbs on the right-hand bar to counteract the pedaling power. This is identical as making use of 75lbf up on the one aspect of the bar and 75lbf down on the opposite; the second on the stem is identical.

Normalizing for Stem Size:

In idea, it’s doable to measure a selected stem of 1 size and extrapolate its outcomes to longer or shorter variations of the identical stem mannequin. In technical phrases, that is “normalizing for stem size.” We will do that as a result of torsional displacement is instantly proportional to size for a tube of a given cross part. It’s true {that a} good engineer will use thinner partitions on shorter stems (which see decrease stresses) and thicker partitions on longer stems (which see increased stresses). Nonetheless, normalizing to size inside a single stem make and mannequin is legitimate to a primary approximation, not less than with steel stems. A composite stem is a unique beast, as a result of layups (AKA laminate schedules) can differ considerably with size.

Whereas torsional displacement is instantly proportional to stem size, bending displacement is proportional to the dice of the size. Our first cross at a stem take a look at setup measures mixed bending and torsional displacement, so it could not be legitimate to extrapolate to longer or shorter stems, even throughout the identical mannequin, not less than if you happen to’re in search of absolute values.

If you happen to’re inquisitive about relative values–for instance, if you wish to know whether or not stem A is stiffer than stem B–then these outcomes ought to be fairly helpful whatever the precise size you propose to make use of.

For this take a look at we used 11cm stems in each case besides 2 (Professional Vibe Dash Carbon and Syntace F119) that are each 10.5cm. The stems had been comparable sufficient in size that we didn’t normalize any stems on this take a look at, however sooner or later we might take a look at some stems that have to be normalized for a good comparability.

Stiffness to Weight Ratio:

This was calculated utilizing =((1/avg. defl) / weight) * 1000

Bolt Materials:

One query we needed to reply was if there was a noticeable distinction between stems with titanium and metal bolts. We chosen just a few random stems and examined them each with titanium and metal bolts and located no significant distinction in deflection in stems with one materials over the opposite.

Mounting Path:

We additionally needed to see if mounting a stem with an increase vs a drop made a distinction within the deflection. Whereas we had been in a position to measure a distinction, lower than 0.1 mm at 100 kilos, it was not sufficient to say that there’s a significant distinction, and was probably throughout the margin of error of the testing.

Notes about Stem Angles:

One different merchandise we needed to check was the distinction in like stems with totally different angles. We examined a few stems which can be obtainable in each 7 and 17 diploma angles and located that 17 diploma stems deflected a median of seven% much less. The examined stems differ from 5 to 10 levels which ought to end in deflection variations of as much as about 3%, so preserve that in thoughts when evaluating two stems of various angles.

Carbon Fiber vs. Aluminum:

Carbon fiber stems don’t provide the burden financial savings that, say, carbon fiber rims do. There’s a motive for this: stems are frequently pressured in 3 ways: bending, torsion and shear. In different phrases, the stresses in a stem are practically isotropic (uniform in all instructions). Carbon fiber is extremely anisotropic (stiffer/stronger in a single route than within the others). Once you attempt to lay up anisotropic carbon to take care of isotropic stresses, you find yourself with what engineers discuss with as “black aluminum,” or pseudo isotropic carbon–and a weight that’s very near an aluminum stem.

There could also be different benefits to a carbon stem; vibration damping is one that’s usually put to the forefront of the controversy. It’s true that composite constructions usually damp vibration higher than metallic ones, and there could also be real-world damping advantages to a carbon stem. One option to take a look at stem damping could be to wire an accelerometer to the stem after which strike it gently with a hammer, studying the accelerometer information to see how shortly the vibrations dissipated. This ring-down take a look at could also be on the Honest Wheel menu for a future article, however is exterior the scope of this take a look at.

Blended supplies:

Hybrid stems, a carbon overlay on an alloy stem. We examined solely a few these however neither did effectively, we’ll do extra testing on others sooner or later to develop our ideas on this medium additional.

We examined two comparable stems one in full alloy (7s) and one in hybrid (vibe carbon) to see if there was a bonus to the hybrid stems. Each are the identical weight and identical dimensions with the identical puzzle lock clamp. The distinction being that the Carbon has thinner alloy, strengthened with carbon. Deflection was noticeably totally different, the complete alloy was considerably stiffer than alloy/carbon.

To take a position on why checks put carbon/aluminum stems on the versatile finish of the spectrum, one would possibly take into account two competing design constraints. First is galvanic corrosion. When aluminum and carbon contact one another, they’ve made a weak battery. The electron-swapping that goes on will trigger an aluminum/carbon half to fail in brief order. To keep away from this, producers use a layer of insulating materials. This layer is commonly a fiberglass/epoxy composite however could possibly be plain epoxy. Neither materials is as stiff as aluminum, so that you’re taking a stiffness loss straight away.

Secondly, the market gained’t tolerate a carbon-wrapped aluminum stem that’s each costlier and heavier than its plain-aluminum counterpart. So producers are compelled to make use of thinner-walled aluminum forgings for his or her carbon-wrapped stems than they do for his or her straight-up aluminum stems. Successfully, they’re changing comparatively stiff aluminum with comparatively compliant fiberglass and/or epoxy.

Making issues worse, some carbon-wrapped aluminum stems use a 0°/90° weave for aesthetic causes. This weave’s stiffness displays the dreaded pseudo isotropy referred to earlier, and is especially compliant in shear–which, in a stem, determines torsional stiffness.

The online result’s a carbon-look stem that has satisfactory energy however extra compliance (and presumably higher vibration damping) than a “pure” aluminum stem.

To be clear, the above is what engineers name a SWAG: a Scientific Wild-Ass Guess. It’s an affordable first cross, however there could also be different elements at play that we haven’t thought-about and which can be additional explored in future checks.